If you own or manage a building with an elevator, you’re in charge of keeping it safe for your occupants. By performing routine maintenance, you can prevent the common breakdowns that put your occupants at risk and slow down your operations. Below, our team from ELEVATE Monitoring discusses everything you should know about elevator preventive maintenance.

Best Maintenance Practices for Elevator Safety, Compliance, and Efficient Operations

Just as your car needs oil changes and tire rotations, your elevators require regular maintenance to continue running smoothly. This upkeep prolongs the lifespan of your equipment, prevents costly repairs, reduces downtime, maintains your service contracts, and ensures safe rides for all your employees or occupants. We recommend the following maintenance practices for elevator safety and longevity.

Routine Inspections

Regular inspections help you catch small issues before a cab gets stuck mid-ride. We recommend scheduling monthly visual evaluations of all elevator components to check for signs of wear, corrosion, or damage. Follow these steps during your inspection:

- Check the doors for smooth and safe operation, ensuring they open and close correctly and at the right speed.

- Inspect the cables and pulleys for fraying or signs of wear.

- Test your emergency communication system to ensure that it functions correctly.

- Check all elevator lights and replace any burnt-out or flickering bulbs.

- Complete annual load tests to ensure your elevator complies with regulatory standards.

- Document your inspection and all performed maintenance for future reference.

Elevator Cleaning

Cleaning is a key aspect of elevator preventive maintenance. Clean components operate smoothly and last longer. You should remove debris from the elevator pit, replace the ventilation filters, and clean any components that look dirty.

Regular Lubrications and Alignments

The elevator’s mechanical components must be properly lubricated and aligned to operate smoothly. Lubrication reduces the friction on moving parts, ensuring everything can glide correctly without wearing down prematurely.

You may be able to lubricate moving parts yourself, but you must choose the correct type of lubricant to avoid causing damage. A professional technician can apply lubrication and inspect the entire system to identify potential misalignments.

Consider adding an annual professional alignment check to your maintenance schedule. This service, completed by licensed elevator technicians, will cover key parts that you might’ve missed during your monthly visual inspections.

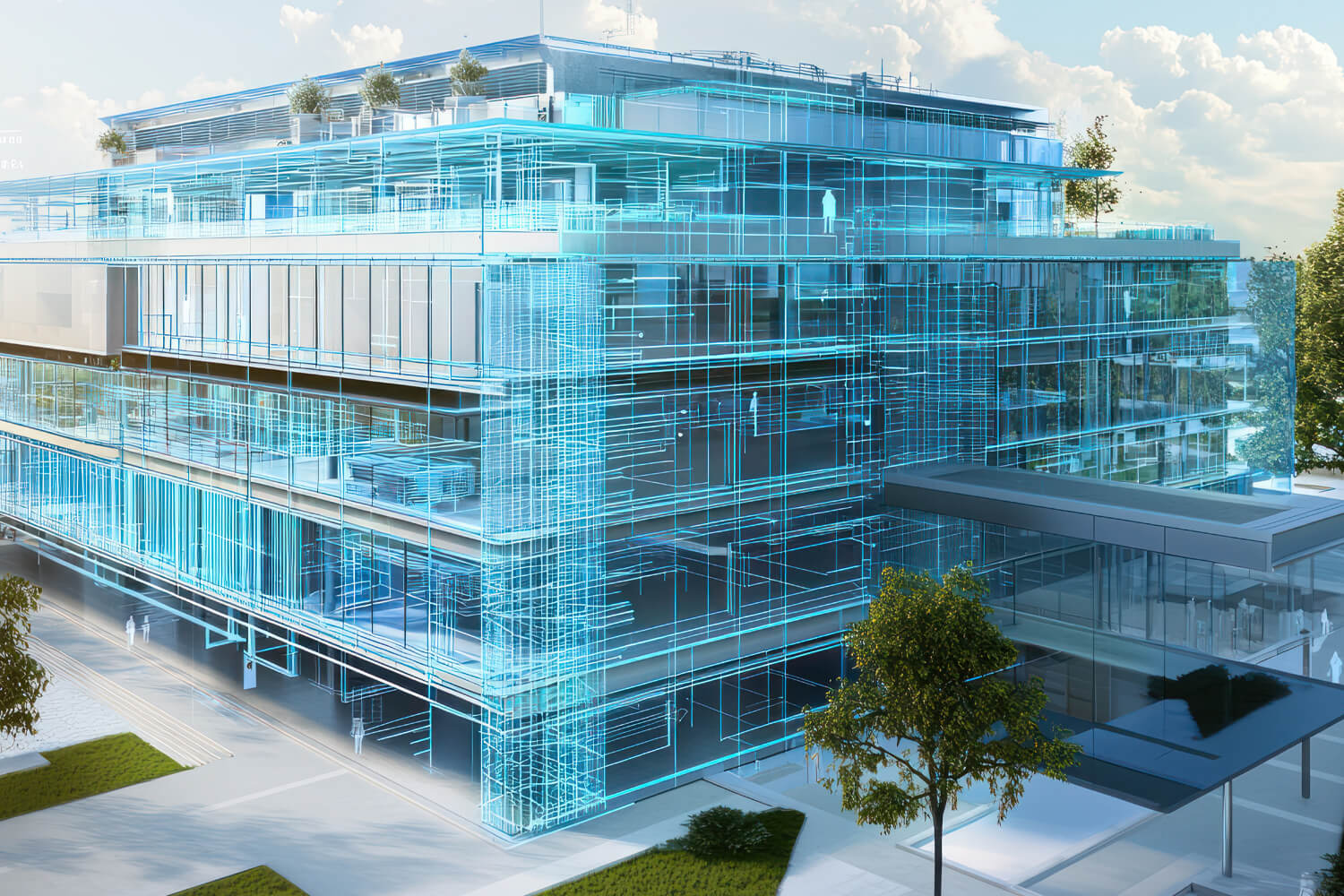

24/7 Performance Tracking

One of the best ways to prevent problems in your elevators is by installing monitoring sensors that can track operations and identify malfunctions the second they happen. This advanced software analyzes usage patterns, recommends exactly when you need to perform maintenance, and sends alerts when something’s wrong. With these real-time insights, you can prevent breakdowns and invest in the right maintenance at the right time for optimal efficiency.

Skip the Guessing Game and Choose ELEVATE Monitoring for Equipment Reliability

Now you know how to perform elevator preventive maintenance. Next, learn about performing an elevator safety audit.

If you’re interested in upgrading the monitoring capabilities and safety of the elevators on your property, you’ve come to the right place. Call ELEVATE Monitoring today at 877-990-9191 to learn more about our two-way monitoring solutions.